Difference between revisions of "Nevermore Systems Descriptions"

(→Batteries: added pics of switches) |

m (Systems Descriptions moved to Nevermore Systems Descriptions) |

||

| (28 intermediate revisions by 3 users not shown) | |||

| Line 17: | Line 17: | ||

== Sails == | == Sails == | ||

| − | + | Catalog of all sails as of 05jun10 | |

| − | * | + | * Mainsail 1 (boat) |

| − | * | + | * Mainsail 2 (missing) |

| − | ** | + | * Genoa ~160%, all-white (boat) |

| − | * | + | * Genoa 124%, blue-trimmed (boat) |

| − | * | + | * Working jib (100%?) (missing) |

| − | + | * Storm jib (48%) (pavilion) | |

| − | * | + | * Trysail (pavilion) |

| − | * | + | * Spinnaker (asymmetric) (boat) |

| − | + | ||

| − | + | === Mainsail === | |

| − | * | + | * Dedicated main halyard winch on starboard on mast |

| − | * | + | * Jiffy (slab) reefing hooks on gooseneck, and dedicated reefing line winch on boom |

| − | + | * 2 jiffy reefing cringles in leech; jiffy lines share the winch on boom with outhaul | |

| − | + | * Dutchman flaking system (Type A) model 40-3A [see Owner's Manual ([http://www.mvbinfo.com/images/sf_om_a.pdf PDF]) or [http://sailing.mit.edu/mediawiki/index.php/Nevermore_Documents Systems Man] reference] | |

| − | ** | + | ** uses 400-lb test monofilament line |

| − | ** | + | ** 2-in dia circular disk fairleads on the sail and 1 2.5-in fairlead for the upper portion of the forward control line |

| − | ** | + | ** halyard is 1/4" black line with cleat on port side of mast; NOTE: recommend that one crew lifts end of boom and another crew at mast tightens the halyard, rather than counting on the halyard to lift the boom |

| − | * | + | * Traveller |

| − | * | + | * Boomvang / preventer |

| − | + | ** as vang, block attaches to fitting at base of mast | |

| − | + | ** as preventer in light air, block attaches to spinnaker toerail snatchblock attachment | |

| − | ** | + | ** for preventer in heavy air, use a dedicated line from end of boom to toerail amidhips toerail, or to bow cleat |

| − | + | ||

| − | + | === Fore Sails === | |

| − | + | * Large genoa: ~ 160%, all-white | |

| − | + | * Smaller genoa: 124% (LP = 9'10"), blue UV protection along the leech | |

| − | * | + | * Working Jib: 100% (boltrope was too large on this sail. It was taken to the sailmaker in 2009 to get a new lufftape. Has not been seen since). |

| − | + | * Foresail furler: | |

| − | + | ** Assembly & Ops manual [[Image:Furlex 200S Furler.pdf|Seldén Furlex 200S]], also see [[http://sailing.mit.edu/mediawiki/index.php/Nevermore_Documents#Furler Docs-aboard List]] | |

| − | + | ** Operation: | |

| − | + | *** keep a little tension on furling line as sail is deployed, to minimize line overwraps in furler drum | |

| − | + | *** keep a little tension on jibsheets while furling, to make a tight roll of sail on the forestay | |

| − | + | **** tension on furling line is considerable for first few turns of drum. however, do not apply too much tension if furler sticks and never use winch handle to furl the jib | |

| − | + | * jib halyard winch: dedicated, port side of mast; | |

| − | + | ** Operation: | |

| − | + | *** The [[Nevermore_Documents#T37_OI|Owner's Instructions page 6]] directs that there be at least 2 turns of WIRE halyard, preferably 4, around the winch with foresails fully hoisted; and never should genoa halyard tension be taken on the rope halyard tail | |

| − | + | *** it follows from the above that we should not consider the deep grooving of the winch drum as being anomalous | |

| − | + | *** it also follows that the wire-to-rope splice will be wrapped on the drum <br>(which ThomS was taught is NOT desired on most boats for integrity of the splice) | |

| − | + | * Storm jib | |

| − | * | + | * Trysail |

| − | ** | + | * Whisker pole: none |

| − | * | + | |

| − | + | [[Image:Nevermore_spinnaker.jpg|right]] | |

| − | + | === Spinnaker === | |

| − | + | * Asymmetric (white with black perched raven) | |

| − | ** | + | * Pole (telescoping aluminum) (at pavilion) |

| + | ** fitting for topping lift, but not for downhaul | ||

| + | ** two mast rings. each off centerline of mast maybe 30-deg to port and to stbd | ||

| + | ** note that we have no reason to think pole was ever used with asymmetric | ||

= Deck Hardware = | = Deck Hardware = | ||

| Line 98: | Line 101: | ||

The keel provides weight for righting moment, and also accommodates the slot for the centerboard. The centerboard is attached to the keel by a single hinge pin at the forward end of the centerboard slot. The centerboard pennant pulls the centerboard up (as opposed to pulling the centerboard down). | The keel provides weight for righting moment, and also accommodates the slot for the centerboard. The centerboard is attached to the keel by a single hinge pin at the forward end of the centerboard slot. The centerboard pennant pulls the centerboard up (as opposed to pulling the centerboard down). | ||

| − | |||

| − | |||

TODO: find weights of keel and centerboard. | TODO: find weights of keel and centerboard. | ||

| + | |||

| + | '''Maintenance''' | ||

| + | |||

| + | See [[Nevermore Documents#T37_OI|Owner's Instructions]] pages 4, 5, 5A for rigging and adjusting the centerboard pennant and tag line, and pages 14, 15, 15A for replacing the pennant. | ||

'''Operation Hints:''' | '''Operation Hints:''' | ||

| − | * | + | * Do not let the pennant run free! I.e., don't let the centerboard drop! |

* The instructions show how to place the block on the pennant so that the tag line will allow full upward position of the CB, and also allow full extension of the CB when the tag line is freed. | * The instructions show how to place the block on the pennant so that the tag line will allow full upward position of the CB, and also allow full extension of the CB when the tag line is freed. | ||

* Simplistic guidelines for deploying the centerboard: | * Simplistic guidelines for deploying the centerboard: | ||

| − | ** deploy down when | + | ** deploy down when beating |

** pull up when running | ** pull up when running | ||

| + | ** deploy down at mooring<!-- per MW --> | ||

** keeping the centerboard down while backing improves steering control | ** keeping the centerboard down while backing improves steering control | ||

| − | |||

= Ship's Machinery = | = Ship's Machinery = | ||

| Line 128: | Line 133: | ||

** a link to the Parts List put on the web by an independent parts supplier | ** a link to the Parts List put on the web by an independent parts supplier | ||

** Westerbeke contemporary [[http://www.westerbeke.com/productBrochures/w50_2.pdf sales brochure]] (1979) (publication LP-1M 10/79) | ** Westerbeke contemporary [[http://www.westerbeke.com/productBrochures/w50_2.pdf sales brochure]] (1979) (publication LP-1M 10/79) | ||

| − | * | + | * Westerbeke Engine electrical system diagrams of 12-V DC circuitry, <br>from Technical Manual, Pub #23156, Ed. one June 1978, which we received with Nevermore |

| − | ** | + | ** [[Engine schematic dgm]] page Q2 |

| + | ** [[Engine wiring dgm]] page Q3 | ||

| Line 167: | Line 173: | ||

[[IMAGE:P1090820-8x6-72p6q.jpg|thumb=P1090820-1p3x1-72p.jpg|Prop, Cutlass, Zincs]] [[IMAGE:P1090887-8x6-72p6q.jpg|thumb=P1090887-1x1o3-72p6q.jpg|Prop]] | [[IMAGE:P1090820-8x6-72p6q.jpg|thumb=P1090820-1p3x1-72p.jpg|Prop, Cutlass, Zincs]] [[IMAGE:P1090887-8x6-72p6q.jpg|thumb=P1090887-1x1o3-72p6q.jpg|Prop]] | ||

| − | The prop | + | The prop on Nevermore is fixed, 2-bladed, diameter approx 15-1/2 inch tip-to-tip. |

Note: the original standard prop was 16-inch fixed two blades [per www.practical-sailor.com Apr 2009 p.14] | Note: the original standard prop was 16-inch fixed two blades [per www.practical-sailor.com Apr 2009 p.14] | ||

| Line 175: | Line 181: | ||

* look for a cutlass bearing model number or other info aboard | * look for a cutlass bearing model number or other info aboard | ||

* can we measure pitch? | * can we measure pitch? | ||

| − | |||

| − | |||

* mark shaft inside the boat for vertical position of blades | * mark shaft inside the boat for vertical position of blades | ||

| Line 184: | Line 188: | ||

=== Wheel, Drive & Quadrant Mechanism, Rudder-Post === | === Wheel, Drive & Quadrant Mechanism, Rudder-Post === | ||

| − | + | Per [[Nevermore_Documents#T37_OI|Owner's manual]] page 8, the Tartan-37 is equipped with an Edson Radial Drive pedestal steering system. | |

| − | + | The "Information on maintenance ... included elsewhere in this manual" can't be found [ThomS Feb08]. | |

| − | + | The "quadrant" is properly a "wheel" at the rudderhead [per Calder]; let's call it the "quadrant" unless talking to e.g. boatyard folk who know the difference; might have to say "rudderhead wheel" do distinguish it from the [steering] "wheel". | |

| − | : | + | TODO: Enter model numbers herein, and see if any ref material is on web. |

=== Emergency Tiller === | === Emergency Tiller === | ||

| − | + | See [[Nevermore_Documents#T37_OI|Owner's manual]] page 8, STEERING | |

| − | + | The tiller handle, a straight aluminum tube, is stored in the stern lazarette for immediate use. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | A bent tube, also a part of the emergency tiller, is left slid over the rudder post to accommodate the tiller handle. | |

| − | + | ||

| − | + | The emergency tiller doesn't allow as much rudder angle as the wheel, and force on the tiller can be considerable. | |

| − | + | ||

| − | + | Emergency steering may be easier, or at least less awkward, with the wheel removed. | |

| − | + | ||

| − | + | The rudder can jam if something falls into the steering quadrant. In this case, neither the wheel nor the tiller will function. | |

=== Autopilot === | === Autopilot === | ||

| Line 298: | Line 299: | ||

== Head == | == Head == | ||

| − | + | Nevermore is equipped with a standard marine toilet and a plastic holding tank. It is a Jabsco Model 29120-2000 Manual Toilet. It is classified as a "Type III Marine Sanitation Device", which means that the waste is not treated, it is simply stored inside the holding tank until it can be pumped out. Waste can be pumped out dockside via the opening on deck, or overboard using the manual pump when more than 3 miles from shore. | |

| − | + | ||

| − | Nevermore is equipped with a standard marine toilet and a plastic holding tank. It is classified as a "Type III Marine Sanitation Device", which means that the waste is not treated, it is simply stored inside the holding tank until it can be pumped out. Waste can be pumped out dockside via the opening on deck, or overboard using the manual pump when more than 3 miles from shore. | + | |

The yellow handled seacock under the sink in the head allows seawater to be pumped into the toilet bowl. This seacock also serves as a scupper for the sink. | The yellow handled seacock under the sink in the head allows seawater to be pumped into the toilet bowl. This seacock also serves as a scupper for the sink. | ||

| − | If the flush valve next to the hand pump is in the "flush" position (vertical), then seawater will be pumped into the bowl when the the hand pump is operated. If the flush valve is in the "pump dry" position (horizontal and to port), then no seawater will be added to the bowl during pumping. | + | If the flush valve next to the hand pump is in the "flush" position (vertical), then seawater will be pumped into the bowl when the the hand pump is operated. If the flush valve is in the "pump dry" position (about 10 degrees below horizontal and to port), then no seawater will be added to the bowl during pumping. |

| − | The hand pump simultaneously pumps seawater into the bowl (if the flush valve is open) and waste out of the bowl. Waste is pumped to the holding tank. The holding tank has a volume of | + | The hand pump simultaneously pumps seawater into the bowl (if the flush valve is open) and waste out of the bowl. Waste is pumped to the holding tank. The holding tank has a volume of 17 gallons. |

The holding tank has three hoses: a 2" inlet, a 2" outlet, and a vent hose. The vent hose leads to the deck. The outlet hose leads to a Y valve. One side of the Y leads to the pump out port on deck. The other side of the Y leads to the sewage out thru-hull, via an anti-siphon valve. | The holding tank has three hoses: a 2" inlet, a 2" outlet, and a vent hose. The vent hose leads to the deck. The outlet hose leads to a Y valve. One side of the Y leads to the pump out port on deck. The other side of the Y leads to the sewage out thru-hull, via an anti-siphon valve. | ||

| Line 314: | Line 313: | ||

'''Maintenance:''' | '''Maintenance:''' | ||

* periodically flush the holding tank and hoses with fresh or salt water | * periodically flush the holding tank and hoses with fresh or salt water | ||

| − | * tighten pump as appropriate to reduce leakage at the handle | + | * tighten pump packing nut as appropriate to reduce leakage at the handle |

| − | * replace pump seals and gaskets every | + | * replace pump seals and gaskets every 2 years or so |

* use head conditioner during winter to reduce holding tank odors | * use head conditioner during winter to reduce holding tank odors | ||

* ensure that hoses do not retain any sewage during boat storage | * ensure that hoses do not retain any sewage during boat storage | ||

| + | |||

| + | '''Jabsco Technical Manual''': [[Image:Jabsco 29090 29120 toilets 0406 data sheet.pdf]] | ||

== Ice Box == | == Ice Box == | ||

| Line 425: | Line 426: | ||

=== Fresh Water Accumulator === | === Fresh Water Accumulator === | ||

[[Image:NevermoreFreshwaterAccumulator.jpg|thumb=NevermoreFreshwaterAccumulator_thumb.jpg|right|Nevermore Fresh Water Accumulator]] | [[Image:NevermoreFreshwaterAccumulator.jpg|thumb=NevermoreFreshwaterAccumulator_thumb.jpg|right|Nevermore Fresh Water Accumulator]] | ||

| + | |||

| + | '''Shurflo''' (Model 182-200) | ||

There is an accumulator downstream from the pump that minimizes water hammer and reduced pump cycling. | There is an accumulator downstream from the pump that minimizes water hammer and reduced pump cycling. | ||

| Line 430: | Line 433: | ||

The accumulator was purchased and installed Summer 2008. | The accumulator was purchased and installed Summer 2008. | ||

| − | ''' | + | '''Specifications:''' |

| + | {| border="0" cellspacing="0" style="margin-left: 10px" | ||

| + | |Serial Number || 719898 | ||

| + | |- | ||

| + | |Pressure || 30 psi | ||

| + | |- | ||

| + | |Manufacture Date || July 2008 | ||

| + | |} | ||

| Line 484: | Line 494: | ||

The switch panel above the nav table is organized into groups | The switch panel above the nav table is organized into groups | ||

of controls including (from left to right): | of controls including (from left to right): | ||

| − | + | <br> | |

| − | # Meters for battery voltage and current | + | # Meters for battery voltage and current (analog) |

# Electric Bilge Pump Switch (switch #01) | # Electric Bilge Pump Switch (switch #01) | ||

# Main Switch Sub-Panel - two horizontal rows of 6 switches or switch/breaker combination | # Main Switch Sub-Panel - two horizontal rows of 6 switches or switch/breaker combination | ||

| − | ## top row has 6 switch/breaker devices (switches #11 - 16) | + | ## top row has 6 switch/breaker devices (switches #11 - 16) <br>note that switch #11 is a "master" for all other horizontal row switches |

| − | ## bottom row | + | ## bottom row has 6 switch/breaker devices (switches #21 - 26) |

| − | # Secondary Vertical Switch Sub-Panel - 7 | + | # Secondary Vertical Switch Sub-Panel - 7 switch/breaker devices (switches #31 - 37 <br>[shown on fiche and photo below] |

| − | # | + | # Meter for battery voltage (digital) - voltage range unknown to this editor<br>[not shown on fiche or photo to right or below] |

* See [[nav_station_switches]] for tables of usages of individual switches. | * See [[nav_station_switches]] for tables of usages of individual switches. | ||

| Line 498: | Line 508: | ||

'''Meters''' (volts and amps) | '''Meters''' (volts and amps) | ||

| − | + | Voltmeter: | |

| − | + | * range 0 - 25 VDC | |

| − | + | * measures voltage into the switch panel from any of the batteries selected by the main battery switch, i.e. shows the voltage of battery #1 or #2 or both batteries in parallel | |

| − | The zero-point for the meter | + | * the analog voltmeter is mirrored by the digital voltmeter to the right of the vertical switch sub-panel described below |

| + | * voltmeter quirk: it appears to read high by approx 1.4 or 1.5 volts. | ||

| + | The zero-point for the meter should be adjusted to read battery voltages | ||

correctly therefore the zero-point will be off-scale. | correctly therefore the zero-point will be off-scale. | ||

| + | <br>Note: a more accurate (digital) voltmeter has been added to the right side of the switch panel | ||

| − | + | Ammeter: | |

| − | + | * range 0 - 50 A | |

| − | + | * reads all current going to all the switches on the switch panel, as provided by the main batteries or the engine generator | |

| − | + | * does not read the current going to the "unidentified system" (see "thick" white wire" below) which exits the control panel box after being connected to the battery/alternator voltage source within the control panel | |

| − | battery charging | + | * does '''not''' read |

| − | battery charging current, so | + | ** any usage by the engine; it especially does not indicate battery charging, which is shown by the ammeter on the engine control panel; <br> note that the engine ammerter ONLY shows battery charging current, so does NOT show any "discharge" current to the ship's systems (like a car ammeter would.) |

| − | does NOT show any "discharge" current to the ship's systems like a car | + | ** any current directed back OUT of the switch box by the approx #06-gauge white wire connected to the INPUT red terminal of the ammeter from the battery switch; this is a subsystem we haven't identified.<br>TODO: trace the white "thick" wire from the ammeter and find the unknown ship's system. |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | TODO: trace the white "thick" wire from the ammeter and find the unknown ship's system. | + | |

| Line 540: | Line 545: | ||

* Twelve combination switches/circuit-breakers arranged in two horizontal rows (switches #11-16 and 21-26). | * Twelve combination switches/circuit-breakers arranged in two horizontal rows (switches #11-16 and 21-26). | ||

| − | * Battery voltage to this sub-panel's switches is OFF unless battery power is ON on one (or more) main rotary battery switch. | + | * Battery voltage to this sub-panel's switches is OFF unless battery power is ON on one (or more) main rotary battery switch under the nav-table seat. |

| − | * No voltage is applied to the remainder of the 11 switches unless the upper-left-most switch of this sub-panel (named "MAIN") is on. | + | * No voltage is applied to the remainder of the 11 horizontal-row switches unless the upper-left-most switch of this sub-panel (named "MAIN") is on. |

* See [[nav_station_switches]] for tables of usages of individual switches. | * See [[nav_station_switches]] for tables of usages of individual switches. | ||

| Line 550: | Line 555: | ||

'''Vertical Switch Sub-Panel''' at Nav Station (switches #31-37) | '''Vertical Switch Sub-Panel''' at Nav Station (switches #31-37) | ||

| − | Note that the horizontal sub-panel's "main" switch does NOT control power to this sub-panel; it is not separately fused. | + | Note that the horizontal sub-panel's "main" breaker/switch does NOT control power to this sub-panel; it is not separately fused. |

* See [[nav_station_switches]] for tables of usages of individual switches. | * See [[nav_station_switches]] for tables of usages of individual switches. | ||

* See [[nav_station_switches_wiring]] for diagrams and discussions. | * See [[nav_station_switches_wiring]] for diagrams and discussions. | ||

| − | |||

| − | |||

'''Nav Instruments Sub-Panel''' | '''Nav Instruments Sub-Panel''' | ||

| + | [[Image:Switchpanel3.jpg|thumb=Switchpanel3_thumb.jpg|right|Nav Instruments Sub-Panel]] '''Nav Instruments Sub-Panel''' | ||

| − | This control subpanel is completely | + | This instrument control subpanel came with the boat in 2007, but is completely removed in 2010. [Its "fiche" is shown on the right, and the panel is mentioned herein because it may be referenced in the operator info for some nav instruments. |

| + | |||

| + | <br><br><br> | ||

| + | |||

| + | '''Voltmeter''' | ||

| + | |||

| + | A digital voltmeter to the right of the vertical switch row displays the main batteries' voltage which is driving all the breaker/switch circuits. | ||

=== Batteries === | === Batteries === | ||

| Line 565: | Line 575: | ||

[[Image:Battery2.jpg|thumb=Battery2_thumb.jpg|right|Battery 2]] | [[Image:Battery2.jpg|thumb=Battery2_thumb.jpg|right|Battery 2]] | ||

[[Image:Battery_switch.jpg|thumb=Battery_switch_thumb.jpg|right|Battery Switches]] | [[Image:Battery_switch.jpg|thumb=Battery_switch_thumb.jpg|right|Battery Switches]] | ||

| + | |||

'''Batteries #1 and #2''' | '''Batteries #1 and #2''' | ||

| Line 572: | Line 583: | ||

* They are located below nav station seat: #2 is fwd, #1 aft | * They are located below nav station seat: #2 is fwd, #1 aft | ||

* Model: Powermaster DC-27P, flooded, 750 MCA, 200 min reserve | * Model: Powermaster DC-27P, flooded, 750 MCA, 200 min reserve | ||

| − | + | <br><br> | |

'''Rotary Battery Switches''' | '''Rotary Battery Switches''' | ||

| Line 579: | Line 590: | ||

* Both have alternator field disconnect (AFD) but they are not wired, hence it is '''very important that at least ONE battery be selected ON''' at all times while the engine is running. | * Both have alternator field disconnect (AFD) but they are not wired, hence it is '''very important that at least ONE battery be selected ON''' at all times while the engine is running. | ||

| − | + | The AFD (alternator field disconnect) contacts on the main switch are not wired to the alternator regulator to inhibit the alternator from producing current if the main switch is turned OFF. | |

| + | Nor is there an alternator protector (West Marine catalog index term) to prevent over-voltage from blowing the alternator's diodes when both batteries are turned "OFF" while running the engine (but we believe Fall 2009) that WM's device is not a good solution to protect the alternator.) | ||

| + | |||

* See [[Main Batteries Usage Strategies]] for instruction and rationales for battery switching and use. | * See [[Main Batteries Usage Strategies]] for instruction and rationales for battery switching and use. | ||

| Line 726: | Line 739: | ||

=== Grounding/Bonding System === | === Grounding/Bonding System === | ||

| − | A copper "backbone" grounding wire (#xx gauge) has been installed low in the boat, running from the bow, | + | A copper "backbone" grounding wire (#xx gauge) has been installed low in the boat, running from the bow, above the bilge, thence toward the stern. Appropriate electrical systems and metallic parts are attached to the grounding by clamps positioned on the cable and near the parts. |

Items that are connected to the "backbone" grounding wire: | Items that are connected to the "backbone" grounding wire: | ||

| Line 733: | Line 746: | ||

** engine | ** engine | ||

** battery "-" returns | ** battery "-" returns | ||

| − | * | + | * forestay |

| − | + | ||

* backstay | * backstay | ||

| + | * shrouds | ||

=== Zinc Guppy === | === Zinc Guppy === | ||

| − | Cable should be cleated on a stern cleat, threaded through ship's wheel, and clipped to backstay. | + | Cable should be cleated on a stern cleat, threaded through ship's wheel, and clipped to backstay. Keep the joint between the cable and the guppy about 1 inch above the water in order to minimize cable/guppy corrosion (the cable corroded at this point and the guppy drowned in the summer of 2008). As of 2007, stern pulpit and lifelines are not grounded. |

[[IMAGE:Zincs-2 new dec07-7x4 72p.gif|thumb=Zincs-2_samples72-thumb.gif|2 Engine zincs]] | [[IMAGE:Zincs-2 new dec07-7x4 72p.gif|thumb=Zincs-2_samples72-thumb.gif|2 Engine zincs]] | ||

| Line 746: | Line 759: | ||

There are two pencil-zincs protecting the engine; one is in the heat exchanger, and one is in the oil cooler. | There are two pencil-zincs protecting the engine; one is in the heat exchanger, and one is in the oil cooler. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

See pp.220-221 Westerbeke Parts List, item 33, #11885 | See pp.220-221 Westerbeke Parts List, item 33, #11885 | ||

| Line 762: | Line 769: | ||

mentions something like "zinc in heat exchanger" (p.20) but doesn't mention one in oil cooler. | mentions something like "zinc in heat exchanger" (p.20) but doesn't mention one in oil cooler. | ||

| + | '''Maintenance History''' | ||

| + | |||

| + | * [[Engine zincs replace 2007]] first replacement by MIT | ||

| + | |||

| + | * [[Engine zincs replace 2007#Engine Zincs Replace 2009|Engine Zincs Replace 2009]] replacement in 2009 | ||

| + | * [[Engine zincs replace 2007#Engine Zincs Replace 2010|Engine Zincs Replace 2010]] replacement in 2010 | ||

[[IMAGE:P1090820-8x6-72p6q.jpg|thumb=P1090820 zincs-thumb.jpg|2 prop-shaft zincs]] | [[IMAGE:P1090820-8x6-72p6q.jpg|thumb=P1090820 zincs-thumb.jpg|2 prop-shaft zincs]] | ||

| Line 768: | Line 781: | ||

=== Zinc on Prop-Shaft === | === Zinc on Prop-Shaft === | ||

| − | [[P1090819-zincs-2007-144p6q]] shows the prop-shaft zincs Fall 2007, printed large enough to show their inhabitants and erosion of the zinc a bit. | + | [[P1090819-zincs-2007-144p6q]] shows the prop-shaft zincs Fall 2007, printed large enough to show their inhabitants and erosion of the zinc a bit. |

| + | |||

| + | '''Maintenance History''' | ||

| + | * two new zincs were installed spring 2008 | ||

| + | * two new zincs were installed may 2010 | ||

=== Anode in Water Heater === | === Anode in Water Heater === | ||

| − | There is a magnesium anode in the water heater. [See [[Systems_Descriptions#water_heater | water heater]] section.] | + | There is a magnesium anode in the water heater. [See [[Systems_Descriptions#water_heater | water heater]] section.] This anode is in the engine fresh cooling water circuit; a zinc anode is NOT applicable. Anodes can be ordered from Raritan; the manual says anode part number is 1790010 for our 12-gallon tank. |

| − | + | ||

| − | + | ||

| − | + | ||

| + | TODO: Locate the anode on the unit and document it | ||

== Lightning Dissipation == | == Lightning Dissipation == | ||

| Line 981: | Line 996: | ||

= Safety Gear = | = Safety Gear = | ||

| + | |||

| + | [[Image:Pfd_red_noharness_info.jpg|thumb=Pfd_red_noharness_info_small.jpg|right|Inflatable PFD w/o Harness]] | ||

== PFD's == | == PFD's == | ||

| − | * West Marine Inflatable PFDs (red, without harness) | + | * West Marine Inflatable PFDs (red, without harness) (stearns model 1131) |

| − | ** | + | ** Use Stearns Rearming Kit 0905 or 0906 (halkey-roberts inflator 840, 25 gram co2, 3/8") |

| − | ** Use Rearming Kit | + | |

| + | [[Image:Pfd_blue_harness_info.jpg|thumb=Pfd_blue_harness_info_small.jpg|right|Inflatable PFD w/ Harness]] | ||

| + | |||

| + | * West Marine 1000 Inflatable PFDs (blue, with harness) (stearns model 1193) | ||

| + | ** Use Stearns Rearming Kit 0932 (33 gram co2) | ||

| + | |||

| + | [[Image:Hoseshoe_info.jpg|thumb=Hoseshoe_info_thumb.jpg|right|Jim-Bouy Horseshoe Throwable PFD]] | ||

| + | |||

| + | == Horseshoe Throwable PFD == | ||

| + | |||

| + | Nevermore has two Type-IV throwable horseshoe PFDs mounted on the stern rail. | ||

| + | * [http://www.jimbuoy.com/pages/marine/horseshoe.htm Jim-Bouy Deluxe Model 1020] with built-in sea anchor. | ||

| + | ** Note that Jim-Bouy is now owned by "Cal-June" | ||

Latest revision as of 09:46, 15 August 2011

This is an exhaustive list of Nevermore's various subsystems.

Contents

- 1 Rigging

- 2 Deck Hardware

- 3 Keel-Centerboard

- 4 Ship's Machinery

- 5 Ship's Electrical Subsystems

- 6 Electronics

- 7 Safety Gear

Rigging

Standing Rigging

Rig Dimensions:

- I: 47.00' (Height of the foretriangle, measured from the highest point of the sail attachment to the sheer line at the point abeam the mast. The point of sheer line is the intersection of the hull and deck)

- J: 16.00' (Horizontal distance from forestay attachment point to front surface of mast)

- P: 41.50' (Maximum hoist of mainsail, measured from lower edge of the upper mast band to the upper edge of the lower mast or upper surface of fixed boom)

- E: 12.00' (Maximum foot length of the mainsail, measured from the after edge of the mast to the inner edge of the band on the boom; Nevermore doesn't have a band, so we say to measure from mast to mainsail clew.

- Est. Forestay Len.: 49.65'

reference: sailboatdata.com

Sails

Catalog of all sails as of 05jun10

- Mainsail 1 (boat)

- Mainsail 2 (missing)

- Genoa ~160%, all-white (boat)

- Genoa 124%, blue-trimmed (boat)

- Working jib (100%?) (missing)

- Storm jib (48%) (pavilion)

- Trysail (pavilion)

- Spinnaker (asymmetric) (boat)

Mainsail

- Dedicated main halyard winch on starboard on mast

- Jiffy (slab) reefing hooks on gooseneck, and dedicated reefing line winch on boom

- 2 jiffy reefing cringles in leech; jiffy lines share the winch on boom with outhaul

- Dutchman flaking system (Type A) model 40-3A [see Owner's Manual (PDF) or Systems Man reference]

- uses 400-lb test monofilament line

- 2-in dia circular disk fairleads on the sail and 1 2.5-in fairlead for the upper portion of the forward control line

- halyard is 1/4" black line with cleat on port side of mast; NOTE: recommend that one crew lifts end of boom and another crew at mast tightens the halyard, rather than counting on the halyard to lift the boom

- Traveller

- Boomvang / preventer

- as vang, block attaches to fitting at base of mast

- as preventer in light air, block attaches to spinnaker toerail snatchblock attachment

- for preventer in heavy air, use a dedicated line from end of boom to toerail amidhips toerail, or to bow cleat

Fore Sails

- Large genoa: ~ 160%, all-white

- Smaller genoa: 124% (LP = 9'10"), blue UV protection along the leech

- Working Jib: 100% (boltrope was too large on this sail. It was taken to the sailmaker in 2009 to get a new lufftape. Has not been seen since).

- Foresail furler:

- Assembly & Ops manual File:Furlex 200S Furler.pdf, also see [Docs-aboard List]

- Operation:

- keep a little tension on furling line as sail is deployed, to minimize line overwraps in furler drum

- keep a little tension on jibsheets while furling, to make a tight roll of sail on the forestay

- tension on furling line is considerable for first few turns of drum. however, do not apply too much tension if furler sticks and never use winch handle to furl the jib

- jib halyard winch: dedicated, port side of mast;

- Operation:

- The Owner's Instructions page 6 directs that there be at least 2 turns of WIRE halyard, preferably 4, around the winch with foresails fully hoisted; and never should genoa halyard tension be taken on the rope halyard tail

- it follows from the above that we should not consider the deep grooving of the winch drum as being anomalous

- it also follows that the wire-to-rope splice will be wrapped on the drum

(which ThomS was taught is NOT desired on most boats for integrity of the splice)

- Operation:

- Storm jib

- Trysail

- Whisker pole: none

Spinnaker

- Asymmetric (white with black perched raven)

- Pole (telescoping aluminum) (at pavilion)

- fitting for topping lift, but not for downhaul

- two mast rings. each off centerline of mast maybe 30-deg to port and to stbd

- note that we have no reason to think pole was ever used with asymmetric

Deck Hardware

Winches

| Winch # | Location | Lewmar Part # | Features | Purpose |

| 1 | cockpit port | 48 ST | 2-speed self-tailing | foresail sheet |

| 2 | cockpit stbd | 48 ST | 2-speed self-tailing | foresail sheet |

| 3 | companionway port | 16 | 2-speed unusable self-tailing |

mainsheet |

| 4 | companionway stbd | 8 | 1-speed unusable self-tailing |

raise/lower centerboard |

| 5 | boom stbd | 8 | 1-speed | mainsail reefing/outhaul |

| 6 | mast port | 30 | 2-speed | foresail halyards |

| 7 | mast stbd | 16 | 2-speed | main halyard |

See Sys_Descript_WINCHES for more comments on maintaining the winches.

Port Cabin Vent

Starboard Cabin Vent

Keel-Centerboard

The keel provides weight for righting moment, and also accommodates the slot for the centerboard. The centerboard is attached to the keel by a single hinge pin at the forward end of the centerboard slot. The centerboard pennant pulls the centerboard up (as opposed to pulling the centerboard down).

TODO: find weights of keel and centerboard.

Maintenance

See Owner's Instructions pages 4, 5, 5A for rigging and adjusting the centerboard pennant and tag line, and pages 14, 15, 15A for replacing the pennant.

Operation Hints:

- Do not let the pennant run free! I.e., don't let the centerboard drop!

- The instructions show how to place the block on the pennant so that the tag line will allow full upward position of the CB, and also allow full extension of the CB when the tag line is freed.

- Simplistic guidelines for deploying the centerboard:

- deploy down when beating

- pull up when running

- deploy down at mooring

- keeping the centerboard down while backing improves steering control

Ship's Machinery

Power Train

Engine

Identifying info from tag on engine:

- model: Westerbeke 50

- horsepower: 41 HP at 3200 RPM (Note that our policy is 2000 RPM)

- serial #: 18P/830A/0247B911

- spec : 18360 2.1

- date : November 1979 manufacture decoded from "0247B911" of serial number

(block #0247 per Svc Bul #132, or of engine per #242; date from "B911" )

REFERENCES:

- Our catalog of engine hardcover and web-based documents, including entries defining

- Tech Manual (ENG_TM), and references to subsidiary tech info on this wiki and on the web

- Westerbeke's Parts List (ENG_PL)

- a link to the Parts List put on the web by an independent parts supplier

- Westerbeke contemporary [sales brochure] (1979) (publication LP-1M 10/79)

- Westerbeke Engine electrical system diagrams of 12-V DC circuitry,

from Technical Manual, Pub #23156, Ed. one June 1978, which we received with Nevermore- Engine schematic dgm page Q2

- Engine wiring dgm page Q3

'Misc observations' (useful in troubleshooting):

- Engine instrument panel gauges (05Sep07):

- Water Temp gauge

- * goes off left (cool) end with sender disconnected (good)

- * sender shows 360 ohm @ 100 deg, 25 ohm @ 230 deg

- Oil Pressure gauge

- * goes off left (0 psi) end with sender disconnected (good)

- (but note: Calder p.288 says most O.P. gauges go to high reading)

- * sender shows 460 ohm @ 0 psi, 44 ohm @ 50 psi, 0 ohm @ 80 psi

- Water Temp gauge

- See Tech Letter #72 page V.4 of Engine Tech Manual

- "Gauges -vs- Senders non-Interchangeability"

- engine mfgr has used 4 different gauge mfgrs for WT & OP, and each

- requires sender by same mfgr; diagrams are given for configs of

- connections for each manufacturer of gauge.

- TODO: define here which make of gauges we have (so tested above),

- and (a) mention it in the 2 sets of resistance readings above,

- and (b) annotate Engine Manual

Transmission

- * Appears to be a "Short Profile Sailing Gear" transmission, HBW Model 10

- (page S.41 of Engine Manual, by comparing it to descriptions of

- about 5 different kinds of transmissions described therein,

- then getting the 5, 10 or 20 size from title in |Parts List)

- * Type of transmission fluid: ATF type A, or Dexron II (per Engine Manual; Dexron III o.k. (per Hansen Marine)

- * fluid quantity (for Model 10): 0.6 litre

Drive Shaft, Coupler, Stuffing Box

Propeller

The prop on Nevermore is fixed, 2-bladed, diameter approx 15-1/2 inch tip-to-tip.

Note: the original standard prop was 16-inch fixed two blades [per www.practical-sailor.com Apr 2009 p.14]

TODO:

- look for a prop model number, and/or look for an info folder aboard

- look for a cutlass bearing model number or other info aboard

- can we measure pitch?

- mark shaft inside the boat for vertical position of blades

Note that aboard is a datasheet for a VARIABLE prop. We think it is for a 2-bladed prop too. A brochure says "Martec low drag propeller." And a 1985 (I think) application for a racing handicap listed Nevermore as having a variable prop. we assume this IMS handicap application was associated with the 1985 Bermuda race.

Steering & Binnacle

Wheel, Drive & Quadrant Mechanism, Rudder-Post

Per Owner's manual page 8, the Tartan-37 is equipped with an Edson Radial Drive pedestal steering system.

The "Information on maintenance ... included elsewhere in this manual" can't be found [ThomS Feb08].

The "quadrant" is properly a "wheel" at the rudderhead [per Calder]; let's call it the "quadrant" unless talking to e.g. boatyard folk who know the difference; might have to say "rudderhead wheel" do distinguish it from the [steering] "wheel".

TODO: Enter model numbers herein, and see if any ref material is on web.

Emergency Tiller

See Owner's manual page 8, STEERING

The tiller handle, a straight aluminum tube, is stored in the stern lazarette for immediate use.

A bent tube, also a part of the emergency tiller, is left slid over the rudder post to accommodate the tiller handle.

The emergency tiller doesn't allow as much rudder angle as the wheel, and force on the tiller can be considerable.

Emergency steering may be easier, or at least less awkward, with the wheel removed.

The rudder can jam if something falls into the steering quadrant. In this case, neither the wheel nor the tiller will function.

Autopilot

According to the Autopilot manual page 8, a basic autopilot system consists of:

- Control Unit (AP11)

- located on port cockpit combing in driver's seat

- Junction Unit (J3000X)

- located on fuel tank bulkhead behind nav station seat

- Drive Unit (no model # page 8, RPU80/RPU180 per diagram page 9)

- located to port of steering quadrant in stern lazaret, attaches to underside of quadrant

- Fluxgate Compass (RFC35) (Serial No.: 13134E02)

- located behind port settee, just forward of nav station.

- front of compass is facing stern so it needs offset correction of 180 degrees during system setup.

- Rudder actuator (is this "Reversible pump RPU80 or 160" listed in the manual?

- location: port quarter, attached to rudder quadrant

- Rudder Feedback Unit (RF300)

- location: aft of steering quadrant, a little stbd of centerline; attaches to top of quadrant

- Course Detector Interface (CD135) (didn't see one; is this optional?)

- Rate Compass (RFC35R) (didn't see one; is this optional?)

- power feed from ship's 12V subsystem

- switch #2 observed on vertical set of Nav station switches (we did not trace this circuit to the system (Fall '07))

STATUS:

- Fall '07:

- we never tried to operate it

- saw NO current load when AUTO PILOT circuit breaker was turned ON;

- expected to see a stand-by current, but it MAY have been too small to observe since AP11 Control Unit max current < 1/2 amp when ON and illumination fully on

- Spring '08:

- turning system ON at steering station Control Unit didn't seem to activate anything

- removed actuator from rudderhead wheel because unit is frozen and steering was jammed

Bilge Pumps

Electric Bilge Pump

Jabsco Water Puppy (Model 18660-0121).

Specifications:

| Body | Bronze |

| Impeller | Neoprene p/n 6303-0001, -0003 nitrite for oil-resistence |

| Voltage | 12 Vdc |

| Amp Draw | 8 amp |

| Fuse Size | 15 amp |

| Port Type | 1/2" Internal Pipe Threads |

| Dimensions | 3 x 4-3/4 x 6-3/8 inches (7.6 x 12.0 x 16.2 cms) |

| Weight | 4-1/2 lb (2 kg) |

More information can be found in the Jabsco Water Puppy Technical Data Sheet

This pump is mounted on the port side of the stern lazarette. A white, corregated plastic ("Bilge-flex"), 3/4" I.D. hose leads from the bilge to the pump. A white, corregated plastic, 5/8" I.D. hose leads from the pump to a through-hull port on the starboard side near the stern. Note that this is the same through-hull fitting used by the manual bilge pump.

The bilge pump is wired directly from battery #1 to the 3-way switch on the nav station breaker panel. The up position manually turns on the pump. The down position puts the pump in automatic mode. When in automatic mode, a "float switch" will turn on the pump when water level in the bilge rises. A 15-amp fuse is inline with the positive lead from battery #1. The yellow rubber fuse holder for this fuse is strapped to the wiring harness that runs directly above battery #1.

| UP | manual: pump runs continuously |

| CENTER | off: pump never runs |

| DOWN | automatic: pump runs when bilge water is more than 4 inches deep |

The electrical float switch (which doesn't actualy float) for the bilge pump is a Jabsco 59400 series Hydro Air Bilge Switch. It is located behind the aft-most panel above the port bench in the cabin (just forward of the nav station). A black plastic air tube runs from the switch to a plastic air bell mounted in the bilge. Rising water in the bilge will increase air pressure in the tube and activate the switch.

More information can be found in the Jabsco Hydro Air Switch Operation Manual.

Manual Bilge Pump

This pump is mounted on stern lazaret to starboard of steering position. Its handle is tied to boat in stern lazaret. A second handle is aboard. Gray corrugated plastic hose, approx 1", leads from bilge to pump.

TODO: define hose to thru-hull, and position of thru-hull.

TODO: define model number, capacity, etc., of pump.

Head

Nevermore is equipped with a standard marine toilet and a plastic holding tank. It is a Jabsco Model 29120-2000 Manual Toilet. It is classified as a "Type III Marine Sanitation Device", which means that the waste is not treated, it is simply stored inside the holding tank until it can be pumped out. Waste can be pumped out dockside via the opening on deck, or overboard using the manual pump when more than 3 miles from shore.

The yellow handled seacock under the sink in the head allows seawater to be pumped into the toilet bowl. This seacock also serves as a scupper for the sink.

If the flush valve next to the hand pump is in the "flush" position (vertical), then seawater will be pumped into the bowl when the the hand pump is operated. If the flush valve is in the "pump dry" position (about 10 degrees below horizontal and to port), then no seawater will be added to the bowl during pumping.

The hand pump simultaneously pumps seawater into the bowl (if the flush valve is open) and waste out of the bowl. Waste is pumped to the holding tank. The holding tank has a volume of 17 gallons.

The holding tank has three hoses: a 2" inlet, a 2" outlet, and a vent hose. The vent hose leads to the deck. The outlet hose leads to a Y valve. One side of the Y leads to the pump out port on deck. The other side of the Y leads to the sewage out thru-hull, via an anti-siphon valve.

There is a vestigial hose remaining from the deck. This hose was used to flush the holding tank with freshwater from a dockside hose. It is no longer attached, and the deck fitting should not be used.

Maintenance:

- periodically flush the holding tank and hoses with fresh or salt water

- tighten pump packing nut as appropriate to reduce leakage at the handle

- replace pump seals and gaskets every 2 years or so

- use head conditioner during winter to reduce holding tank odors

- ensure that hoses do not retain any sewage during boat storage

Jabsco Technical Manual: File:Jabsco 29090 29120 toilets 0406 data sheet.pdf

Ice Box

The Alder/Barbour ice box system is cooled by ice or by DC refrigerating system. There are two levels in the cooler, separated by a wood lattice. Water from the ice box drains to the bilge. The refrigeration system has two parts, a compressor (mounted in the starboard lazarette) and an evaporator (located in the ice box). The thermostat is located in the back (outboard) part of the ice box.

The ice box is mentioned in the Owners Manual page 11.

STATUS: as of 07 Mar 2010, both the compressor and the thermostat have been removed from the boat.

TODO: record volume of ice box

Compressor

Danfoss BD2,5 102N3111

Stove

There is an alcohol stove/oven in the galley. The master shutoff is located just to port of the sink (next to the stairway). The unit is gimbaled for use underway, and there are clamps to keep pots positioned on the stove over the burners.

See T37 Owner's Instructions pages 16-17 for operation of the stove.

Based on experiences on Aleida with the same kind of stove, a few items of these instructions should be highlighted.

- The statement that "the gas is burned in much the same manner as in a home gas stove" is literally true, but somewhat misleading because it might imply that one turns on the gas, lights the stove, and is ready to cook. However, the steps 7, 8, 9, and part of 10 -- which comprise turning on the fuel [not yet a gas] and lighting the stove, imply a more complicated situation, and with good reason.

- Especially step 7 -- wherein we get some alcohol into the lower part of the burner -- is important to get right. We can suggest looking in the burner with a flashlight as the valve is turned on to "watch the alcohol flowing into the little pan," to make SURE not to get too much fuel in the little cup. Maybe the "one turn" on is an excessive amount to turn the valve on, unless the stove hasn't been used for awhile. In fact, with the valve open about 1/3 to 1/2 turn, as soon as you see any alcohol appear in the pan it'll be almost too much by the time you close the valve.

- Part of the instructions in step 8 include "if the flames are licking at the overhead, ... extinguish with water." So think about it: if you're gonna boil some water anyway, why not draw it BEFORE your first times at lighting the stove.

- We note that step 11's order of turn-off (master shut-off valve first, then burner valve) may be different from instructions in the paperwork that came with the stove, and was not used on Aleida as far as I [ThomS] knows. However, it does give a more safe condition for the stove when it isn't being used, by purging pressure from the fuel line before turning off the master shut-off valve.

Maintenance:

- clean stove top and oven after each use

- Clean out any spillage under the burners if a cooking utinsil overflows, after the burners cool.

- periodically flush and clean the alcohol tank

Fresh Water System

Page 10 of the T37 Owner's manual describes operation and maintenance of the fresh water system. The freshwater system has been modified, especially concerning filling the tanks, as mentioned later below. Nearly the entire freshwater system was replaced in August 2008.

The fresh water system is supplied by 2 tanks, a 30-gallon tank on the port side, and a 60-gallon tank on the starboard side. Each tank has 2 inspection ports which are easily accessed through the lower berth/bench on either side of the main cabin.

Valves under the cabin floor connect the two tanks. Either tank can supply water to the ship's fresh-water system, or both tanks can be linked together.

There are two fill fittings on the starboard deck; the forward fill fitting fills the port tank, and the aft fitting fills the starboard tank.

The original configuration had only ONE fill fitting. Nevermore's copy of the owner's manual has been marked up to indicate how to fill both tanks (the original configuration required filling the port tank through the starboard tank.)

Note the admonition (also on page 10, in the "HOT WATER" section) that the fresh-water pump should be ON while heating water using 110-volt shore power. The water is usually warmed by the engine's fresh-water cooling water. Heating water in this way does not require the pump to remain ON. In fact, there is no control to turn heating from the engine on or off.

This rough sketch of the water system was used (2007-08) to replace all the freshwater hoses; it indicates all associated devices and parts, and indicates their interconnections.

Maintentance:

- when underway, do not open both freshwater tank valves

Fresh Water Pump

Jabsco Par-Max 3.0 (Model 31395-3000).

Specifications:

| Voltage | 12 Vdc |

| Amp Draw | 5.2 amp @ 10 PSI |

| Fuse Size | 10 amp |

| Flow | 3.0 GPM |

| Ports | "Snap-Fit" ports with 1/2" hose adapters |

| Dimensions | 9 x 4.2 x 4.75 inches |

| Weight | 4-1/2 lb (2 kg) |

The water pressure pump is located just forward of the starboard tank, under the lower berth. Diaphram design allows pump to run dry without damage. Internal pressure sensor stops the pump when working pressure is acheived.

The freshwater pump was purchased and installed Summer 2008.

Maintentance:

- do not run the pump when tanks are empty or supply valves are closed

- drain completely in winter to avoid freezing

Fresh Water Strainer

Jabsco Pumpgard (Model 36400-0000)

Water from one or both tanks is filtered by a steel screen strainer which is inline just before the water pump. The strainer can be cleaned by unscrewing the plastic cover from the top, removing the cylindrical screen, and rinsing it out with fresh water.

The strainer was purchased and installed Summer 2008.

Maintenance:

- periodically clean filter if clogged

Fresh Water Accumulator

Shurflo (Model 182-200)

There is an accumulator downstream from the pump that minimizes water hammer and reduced pump cycling.

The accumulator was purchased and installed Summer 2008.

Specifications:

| Serial Number | 719898 |

| Pressure | 30 psi |

| Manufacture Date | July 2008 |

Water Heater

There is a water heater located beneath the cockpit floor in the center of the boat. Water is heated by engine coolant and/or 100V AC.

The water heater was installed by (barely) fitting it through the engine access panels on the port side of the engine, via the navigation berth. It will not fit through the starboard lazarette opening.

This unit was purchased and installed Spring 2008.

Raritan 1700 12-gallon, 120V heater, Model #171211

Specifications:

| Electrical Recovery Rate | 13 gallons (49.2 liters) per hour |

| Maximum Operating Pressure | Tank: rated at 150 psi (1034kPa) Pressure Valve: 50 psi (345kPa) |

| Current Draw | 10 amps (120V AC) |

| Circuit Breaker | 15 amps |

| Thermostat | Adjustable; Factory Set to 120°F (49°C) |

| Anode | Magnesium |

| Dimensions | ? |

Maintenance:

- the magnesium anode should be checked once per year; see more info in Anti-Electrolysis section

Ship's Electrical Subsystems

The 12-volt DC wiring circuits and the 110-volt AC circuits are functionally and electrically isolated from one another, except for the 12-volt battery charger which is powered by 110-volt AC shore power. DC-to-AC ground isolation must be performed within the charger.

The Tartan 37 wiring diagram provided in the Owner's Instructions can be used as a general guide to Nevermore wiring. However, this Oct 1976 drawing is different from the 1980 as-built configuration as we deduce it, as discussed in comments to the wiring diagram.

The as-received (2007) configuration of wiring will be discussed in sections for 12-V DC and the subsection battery charger, and in section 120-V AC below.

12-Volt DC

The switch panel above the nav table is organized into groups

of controls including (from left to right):

- Meters for battery voltage and current (analog)

- Electric Bilge Pump Switch (switch #01)

- Main Switch Sub-Panel - two horizontal rows of 6 switches or switch/breaker combination

- top row has 6 switch/breaker devices (switches #11 - 16)

note that switch #11 is a "master" for all other horizontal row switches - bottom row has 6 switch/breaker devices (switches #21 - 26)

- top row has 6 switch/breaker devices (switches #11 - 16)

- Secondary Vertical Switch Sub-Panel - 7 switch/breaker devices (switches #31 - 37

[shown on fiche and photo below] - Meter for battery voltage (digital) - voltage range unknown to this editor

[not shown on fiche or photo to right or below]

- See nav_station_switches for tables of usages of individual switches.

- See nav_station_switches_wiring for diagrams and discussions.

Meters (volts and amps)

Voltmeter:

- range 0 - 25 VDC

- measures voltage into the switch panel from any of the batteries selected by the main battery switch, i.e. shows the voltage of battery #1 or #2 or both batteries in parallel

- the analog voltmeter is mirrored by the digital voltmeter to the right of the vertical switch sub-panel described below

- voltmeter quirk: it appears to read high by approx 1.4 or 1.5 volts.

The zero-point for the meter should be adjusted to read battery voltages

correctly therefore the zero-point will be off-scale.

Note: a more accurate (digital) voltmeter has been added to the right side of the switch panel

Ammeter:

- range 0 - 50 A

- reads all current going to all the switches on the switch panel, as provided by the main batteries or the engine generator

- does not read the current going to the "unidentified system" (see "thick" white wire" below) which exits the control panel box after being connected to the battery/alternator voltage source within the control panel

- does not read

- any usage by the engine; it especially does not indicate battery charging, which is shown by the ammeter on the engine control panel;

note that the engine ammerter ONLY shows battery charging current, so does NOT show any "discharge" current to the ship's systems (like a car ammeter would.) - any current directed back OUT of the switch box by the approx #06-gauge white wire connected to the INPUT red terminal of the ammeter from the battery switch; this is a subsystem we haven't identified.

TODO: trace the white "thick" wire from the ammeter and find the unknown ship's system.

- any usage by the engine; it especially does not indicate battery charging, which is shown by the ammeter on the engine control panel;

Electric Bilge Pump Switch

- OFF, AUTOMATIC, or MANUAL operation of the single bilge pump.

- Voltage is ALWAYS on to this switch, even when main rotary switches are OFF.

- It is always connected to power from Battery #1, through an inline fuse located in the wiring harness above the battery. Removing the fuse removes voltage from the main panel's bilge-pump circuits.

- See Electric Bilge Pump

A note on terminology: The terms "bilge" and "sump" are synonymous on Nevermore; Tartan's original "sump" was a separate catch-basin for ice box and shower water, while "bilge" was used normally. As far as we know (Sep07), the "sump" isn't used any more, and we use the 3-way switch to provide

- TODO: mark up T37 Owner Manual page 11 to NOT talk about the "sump".

- TODO: check whether the refigerator (ice box) still drains water into any kind of sump.

Main Switch Sub-Panel (horizontal switches)

- Twelve combination switches/circuit-breakers arranged in two horizontal rows (switches #11-16 and 21-26).

- Battery voltage to this sub-panel's switches is OFF unless battery power is ON on one (or more) main rotary battery switch under the nav-table seat.

- No voltage is applied to the remainder of the 11 horizontal-row switches unless the upper-left-most switch of this sub-panel (named "MAIN") is on.

- See nav_station_switches for tables of usages of individual switches.

- See nav_station_switches_wiring for diagrams and discussions.

Vertical Switch Sub-Panel at Nav Station (switches #31-37)

Note that the horizontal sub-panel's "main" breaker/switch does NOT control power to this sub-panel; it is not separately fused.

- See nav_station_switches for tables of usages of individual switches.

- See nav_station_switches_wiring for diagrams and discussions.

Nav Instruments Sub-Panel

Nav Instruments Sub-PanelThis instrument control subpanel came with the boat in 2007, but is completely removed in 2010. [Its "fiche" is shown on the right, and the panel is mentioned herein because it may be referenced in the operator info for some nav instruments.

Voltmeter

A digital voltmeter to the right of the vertical switch row displays the main batteries' voltage which is driving all the breaker/switch circuits.

Batteries

Batteries #1 and #2

- Batteries #1 & #2 controlled by top main rotary switch.

- They are "mixed use" (starting and deep discharge) batteries of the same type

- They are located below nav station seat: #2 is fwd, #1 aft

- Model: Powermaster DC-27P, flooded, 750 MCA, 200 min reserve

Rotary Battery Switches

- The two rotary battery switches are Guest 2300A, 360-amp, 600-amp momentary.

- Only the top switch is in use. Do not use the bottom switch.

- Both have alternator field disconnect (AFD) but they are not wired, hence it is very important that at least ONE battery be selected ON at all times while the engine is running.

The AFD (alternator field disconnect) contacts on the main switch are not wired to the alternator regulator to inhibit the alternator from producing current if the main switch is turned OFF. Nor is there an alternator protector (West Marine catalog index term) to prevent over-voltage from blowing the alternator's diodes when both batteries are turned "OFF" while running the engine (but we believe Fall 2009) that WM's device is not a good solution to protect the alternator.)

- See Main Batteries Usage Strategies for instruction and rationales for battery switching and use.

- See Main 12-volt Control Schematic Diagram which includes schematic (graphic) and a walk-thru of circuitry (text).

Tri-Color/Anchor/Strobe

- Model: Aquasignal Series 40: tricolor / anchor / strobe, quicfits (Model # 40806)

- "Quicfits" connector means that the unit can be easily unclipped from the top of the mast by sqeezing the black tabs at the bottom of the unit and pulling the whole assembly up.

- Bulbs:

- tricolor: 12V, 25W, 15D bayonet base (Aquasignal Part# 90002)

- anchor: 12V, 10W, 15D bayonet base (Aquasignal Part# 90005)

- strobe: 12/24V, 8W, Xenon Strobe (Aquasignal Part# unknown - maybe 90009)

- Visibility (from Aquasignal website):

- tricolor: 2nm

- anchor: 2nm

- strobe: 3nm

- Aquasignal Website

Steaming/Foredeck Light

Make and model is unknown. Similar models use 10W bulbs for steaming light and 20W flood bulbs for foredeck illuminaton.

- TODO: determine make and model

- TODO: determine bulb types

Sidelights

The sidelight fittings have red and green lenses. They use a double-contact bayonet-base bulb. Base-diameter is 19/32", and bulb is 1-3/8" long. Nevermore's sidelights are required to have 1 Candlepower (cp) of luminous intensity.

Bulbs that came with Nevermore are 12v, 3W, 4.5cp, such as Seadog Part# 441032-1.

As of August 2009, two spare bulbs were aboard, Ancor Part# 520090: 12v, 7.5W, 6cp.

Sternlight

- TODO: determine bulb type

120-V AC Battery Charger

Xantrex Truecharge 10TB Multistage Battery Charger.

This charger uses microprocessor-controlled three-stage charging:

- Bulk: Replaces 70-80% of the battery’s state of charge at the fastest possible rate.

- Absorption: Replenishes the remaining 20-30% of charge, bringing the battery to a full charge at a slow, safe rate.

- Float: Voltage is reduced and held constant in order to prevent damage and keep batteries at a full charge.

Specifications:

| Output current | 10 A @ 14.5 V nominal |

| Output voltage (charge) | 14.2 - 14.4 VDC |

| Output voltage (float) | 13.5 - 13.8 VDC |

| Input voltage | 90-135 VAC, 50/60 Hz) |

| Number of battery banks | 2 |

| Configurable battery settings | Sealed (Gel & AGM) / Flooded |

| Recommended battery size | 25 Ah to 100 Ah |

| Dimensions (H x W x L) | 2.75 x 6.7 x 15.1 inches |

| Weight | 3 lb |

| AC Connector | 3-prong 15A household plug |

| DC Connectors | Two 2-pin molex connectors |

Documentation on this charger:

- File:Xantrex Truecharge10B OwnersManual.pdf

- File:Xantrex Truecharge10B DataSheet.pdf

- File:Xantrex Truecharge10B TechNote.pdf

Note: This charger is not yet installed. See the Upgrade 120v Electrical System task for more details.

The previous battery charger was Battery Charger Raritan R3012-3. It was removed from the boat in July, 2008.

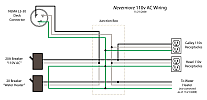

120-volt AC

120-volt AC power is supplied to the ship via a standard male twist-lock shore power connector (NEMA type L5-30), mounted on the exterior of the port-side cockpit coaming by the stern.

- Note: The shore power is the aft-most of 2 connectors. The other connector was for "phone" and is completely disconnected.

Two switches/breakers are mounted on the aft side of the "Emergency" supplies cabinet next to the nav station. The Tartan documentation lists these as 20-amp breakers, although no amperage is designated on the actual breakers.

The left breaker is labeled "110 V AC" and supplies power to standard household AC receptacles (NEMA type 5-15). One pair of receptacles is above the galley sink, and another pair of receptacles on the aft side of the sink cabinet in the head.

The right breaker is labeled "WATER SYSTEM" and supplies power to the water heater. The power cable to the water heater is not connected (as of Nov 21 2008). The "110 V AC" breaker does not need to be switched on for the water heater to work. However, the Owner's Instructions pp. 10-11 demands that -- when the water heater 110V breaker is ON -- the freshwater pump must also be left ON.

All 120v cables terminate in a round plastic junction box located on the port side, just forward of the nav station, in a cabinet where life jackets are stowed.

- Note: The ground connectors of all receptacles and cables are all connected together but none are connected to the DC grounding/bonding system of the boat.

The Tartan 37 wiring diagram provided in the Owner's Instructions Section V presents the 120V-AC circuitry on Nevermore as MIT received her, except that the battery charger isn't shown. (Remember that the 12V-DC circuitry on this schematic can only be a general guide to some circuit configurations.) Note that this diagram explicitly states that "shore power is totally independent from ship's ground;" i.e., it is unlikely any galvanic isolator or isolation transformer was removed from the boat like one might think.

The diagram below shows the 120V-AC configuration after the battery charger that came with Nevermore was removed.

Miscellaneous notes:

- Two shore power cords are aboard, both with 30A (120-volt) locking connectors. Each is probably 25 foot length or more.

- Three or four short converter cables convert from male "marine" locking connector (on dock) to 3-pin "household" female; "household" male to "marine" female to the boat; don't remember the 2 others, probably e.g. 120-volt 50-amp locking male to 20/30-amp and/or 1 leg of 240-volt locking male to 20/30-amp locking female.

TODO:

- define and implement AC -vs- DC grounding circuit and circuit breakers to

- provide isolation of AC & DC grounds to preclude galvanic action on ships parts

- provide safety grounding and circuit-breakers to prevent crew electrocution or fires for a mis-wired AC feed

- check the config of the 2 short converter cords Thom can't remember what are (see above).

- measure length of the two long cords.

- define steps for polarity checking of the shore power source: for example, something like:

- first choose shore power adaptor to get to 30-amp shore-power receptacle (if required);

- use shore-power -to- flat-pin ("household") connector to then use ground-test lights unit to check the dock's configuration; (use boat end of shore-power cable if dock power is 30-amp connector)

- connect shore-power cable to boat;

- (can also) use ground-test lights unit in ship's flat-pin receptacles.

Anti-Electrolysis

See also discusssion of Electrolysis (AKA "galvanic corrosion" and "stray-current corrosion".)

Grounding/Bonding System

A copper "backbone" grounding wire (#xx gauge) has been installed low in the boat, running from the bow, above the bilge, thence toward the stern. Appropriate electrical systems and metallic parts are attached to the grounding by clamps positioned on the cable and near the parts.

Items that are connected to the "backbone" grounding wire:

- terminal block with 12-volt grounding of

- engine

- battery "-" returns

- forestay

- backstay

- shrouds

Zinc Guppy

Cable should be cleated on a stern cleat, threaded through ship's wheel, and clipped to backstay. Keep the joint between the cable and the guppy about 1 inch above the water in order to minimize cable/guppy corrosion (the cable corroded at this point and the guppy drowned in the summer of 2008). As of 2007, stern pulpit and lifelines are not grounded.

Zincs in Engine

There are two pencil-zincs protecting the engine; one is in the heat exchanger, and one is in the oil cooler.

See pp.220-221 Westerbeke Parts List, item 33, #11885

- pencil-zinc in heat exchanger item 23

- pencil-zinc in lube oil cooler item 32

Engine Parts List (ENG_PL) Parts List (or [web version]) indicates one part number for both zincs. However, the two are not the same size. The OC's zinc size (both diamater of screw threads and of zinc) that West Marine sells is too long. The photos page shows the OC zinc against a ruler which shows a workable pencil length, namely 1.6 inches from end of screw threads.

The Engine Tech Manual (ENG_TM) mentions something like "zinc in heat exchanger" (p.20) but doesn't mention one in oil cooler.

Maintenance History

- Engine zincs replace 2007 first replacement by MIT

- Engine Zincs Replace 2009 replacement in 2009

- Engine Zincs Replace 2010 replacement in 2010

Zinc on Prop-Shaft

P1090819-zincs-2007-144p6q shows the prop-shaft zincs Fall 2007, printed large enough to show their inhabitants and erosion of the zinc a bit.

Maintenance History

- two new zincs were installed spring 2008

- two new zincs were installed may 2010

Anode in Water Heater

There is a magnesium anode in the water heater. [See water heater section.] This anode is in the engine fresh cooling water circuit; a zinc anode is NOT applicable. Anodes can be ordered from Raritan; the manual says anode part number is 1790010 for our 12-gallon tank.

TODO: Locate the anode on the unit and document it

Lightning Dissipation

Nevermore has NO specific mechanisms for lightning dissipation.

Electronics

Fathometer

Model: Datamarine SL200DL

Serial No.: 012726

Depth Transducer:

- Model: Airmar B17 "Retractable Low Profile"

- Frequency: 200kHz

- Part No. (on cable tag): 31-241-3-01

- Purchased new: May 2008

Powered on by "NAV INST" circuit breaker on Nav Station Switch Panel 1. "MAIN" breaker switch must be on.

Tested on Aug 11, 2008. Depth sounder reads 25 feet in 28 feet of water.

Knotmeter

Model: Datamarine DCS100

This instrument is missing. It was last seen Fall 2007.

The speed transducer is in the posession of Ted Young.

The "dummy plug" core is in place in the boat.

Windmeter

Model: Datamarine LX360

Serial No.: 012128

GPS - Fixed Mount

Model: Garmin GPSMAP 276C

Software Revision: 5.20 (current as of Jun 9, 2008)

Specifications:

| Unit dimensions: WxHxD | 5.7" x 3.2" x 1.9" (14.5 x 8.1 x 4.8 cm) |

| Display size: WxH | 3.0" x 2.2" (7.6 x 5.6 cm) |

| Display resolution | 480 x 320 pixels |

| Display type | 256-color TFT |

| Weight | 13.6 oz (385 g) |

| Battery | rechargeable internal lithium-ion |

| Battery life | up to 15 hours |

| Waterproof | yes (IPX7) |

| Antenna | detachable 50-ohm BNC |

| NMEA input/output | NMEA 0183 |

| Basemap | yes |

| Built-in memory | none (cannot load maps to internal memory) |

| Accepts data cards | Garmin data cards |

| Waypoints | 3000 |

| Routes | 50 |

| Track log | 10,000 points |

Features:

- Garmin sonar compatible: yes

- Supports DSC (displays position data from DSC capable VHF radio): yes

- Audible alarms: yes

- Tide tables: yes

- Hunt/fish calendar: yes

- Sun and moon information: yes

- Automatic routing (turn by turn routing on roads): yes

- Headphone jack/audio line-out: yes

Garmin Chart Cards:

- Bluechart: Cape Cod: Model US003R (Jun 2007)

- Gloucester through New London, including Narragansett Bay, Block Island, Martha's Vineyard, Nantucket Island, the entire Cape, and includes general coverage Georges Bank

- Bluechart: South Maine: Model US002R (< 2006)

- Penobscot Bay through Gloucester, including Casco Bay and Cape Ann

Documentation:

GPS - Handheld

Manufacturer: Magellan

Location: drawer under nav station

RADAR

- Display: Raytheon R20XX display unit (mounted to the left of the nav station)

- Antenna: Raytheon R20XX raydome antenna (mounted on the mast)

Status (May 23, 2008) System has been tested "on the bench" and appears to function correctly. See full status report

TODO:

- add on-board manuals to Nevermore_Documents list of hardcopy documents

(but a question: that list says the detailed info about these manuals will be found HERE...?) - add URL http://raymarine.com/raymarine/SubmittedFiles/Handbooks/Legacy_Handbooks/radar/R20XX-R21XX.pdf to the docs list too

RADAR detector

C.A.R.D. (Collision Avoidance Radar Detector)

- Manufacturer: Survival Safety Eng., Inc.

- Model No.: 060

- Serial No.: 9140470604

Detects radar signals from other boats and sounds alarm and indicates octant of bearing to the ship.

Not installed as of June 9, 2008

VHF Radio - Fixed Mount

Tranceiver:

Model unknown

Coax Cable:

- 16(19X29) stranded tinned-Cu center conductor

- Foam dielectric

- Type IIA white marine jacket

- Nominal Impedance 50 Ohm

- Velocity of propagation 78%

- Outer diameter .242"

- 98% tinned Cu braid.

- installed new cable in mast: May 2008

VHF Antenna:

- Manufacturer: Digital Antenna

- Model: 200 Series: 222-VW

- 3-foot stainless steel antenna mast

- Quick antenna mast disconnect

- Connector: UHF female (SO239)

- Impedance: 50 ohms

- Max Power: 100 watts

- 3dB gain

- VSWR: < 1.2:1 @ 156.8 MHz

- Ordered new: May 2008

VHF Radio - Hand-held

Model: Icom VHF Marine Tranceiver IC-M34

- Serial No.: 0115406

Features:

- Submersible (1m depth for 30 min.)

- Dual/Tri-watch functions

- Weather channel reception

- Auto Scan function

Charger: Icom Desktop Charger BC-173

Specifications:

| Transmit Frequencies | 156.025 - 157.425 MHz |

| Receive Frequencies | 156.050 - 163.275 MHz |

| Usable channels | INT, USA, CAN, WX channels |

| Type of emission | 16K0G3E (FM) |

| Transmit Current (at 5W output) | 1.5A |

| Receive Current (at AF max.) | 200mA |

| Antenna Impedance | 50 ohms (SMA) |

| Dimensions (WxHxD) | 2-7/16" x 3-13/16" x 1-17/32" (62 x 97 x 39 mm) |

| Weight | 10.8oz (305g) |

| RF output power (Hi/Low) | 5W, 1W (2W w/ alkaline batteries) |

| Audio output power | 0.35 W |

Safety Gear

PFD's

- West Marine Inflatable PFDs (red, without harness) (stearns model 1131)

- Use Stearns Rearming Kit 0905 or 0906 (halkey-roberts inflator 840, 25 gram co2, 3/8")

- West Marine 1000 Inflatable PFDs (blue, with harness) (stearns model 1193)

- Use Stearns Rearming Kit 0932 (33 gram co2)

Horseshoe Throwable PFD

Nevermore has two Type-IV throwable horseshoe PFDs mounted on the stern rail.

- Jim-Bouy Deluxe Model 1020 with built-in sea anchor.

- Note that Jim-Bouy is now owned by "Cal-June"